TRASH 2 RESOURCES

We humans are the only creatures on Planet Earth that produce waste. In fact, we invented the word “waste”. Before man stepped foot on Planet Earth, absolutely everything was recycled naturally. Our modern day lifestyles of convenience, our farming practices, our food chain production & distribution, and quite literally everything we touch has a component of “waste” associated with it.

typical landfill – #circulareconomy

THE CHALLENGE

- Our governments spend millions of tax payer dollars every year trucking waste to landfill on the outskirts of the centres.

- Waste pilling up in landfills not only pollutes the air with harmful GHG’s, it also pollutes rivers and underground aquifers that we and wildlife downstream depend on.

- Landfills also encourage the development of densely populated slums around its borders. With very little policing and lack of schooling, gangs form and a few. host of antisocial activities become commonplace. Drug addiction and peddling, prostitution, child abuse, robberies and mugging, and more serious criminal activities just to mention a few.

- To compound matters, charcoal the primary cooking fuel used by the millions of low income dwellings around every city and town are burning down our forests at a non-recoverable rate.

- From a different perspective, increased cases of cancer are directly linked to the chemicals used in our food production. Conventional agriculture practices encourage the use of chemicals from herbicides before and planting and during growth, chemical fertilisers, chemical pesticides and fungicides, and even post-harvest chemicals in stored grains and other farm produce. This is compounded by misleading and inappropriate sale of chemical to unsuspecting farmers by unscrupulous agro-vet dealers just to make a quick buck.

Unless there is an immediate and deliberate attempt to reduce the use of charcoal, the Sahara desert will move in-house Kenya.

The Solution ?

GREEN RECYCLE MARKET’s

1. Managing Waste at Source

2. Reusing, Recycling & Repurposing Everything

3. Nutrient Circular Economy

4. Clean Green Energy

HOW IT WORKS

It’s quite simple.

Instead of trucking tons of organic waste from estates, market places, street corners etc all the way across town to city dumpsites and landfills – sometimes miles away in another county altogether, our model proposes setting up large capacity T-Rex digesters smack in the middle of the populated areas and market places where large volumes of organic waste is generated. Keeping in mind that 70% of waste ending up in landfills is organic, this means that with the bulk being processed onsite or at source, means the remaining 20 – 30% can more easily be managed.

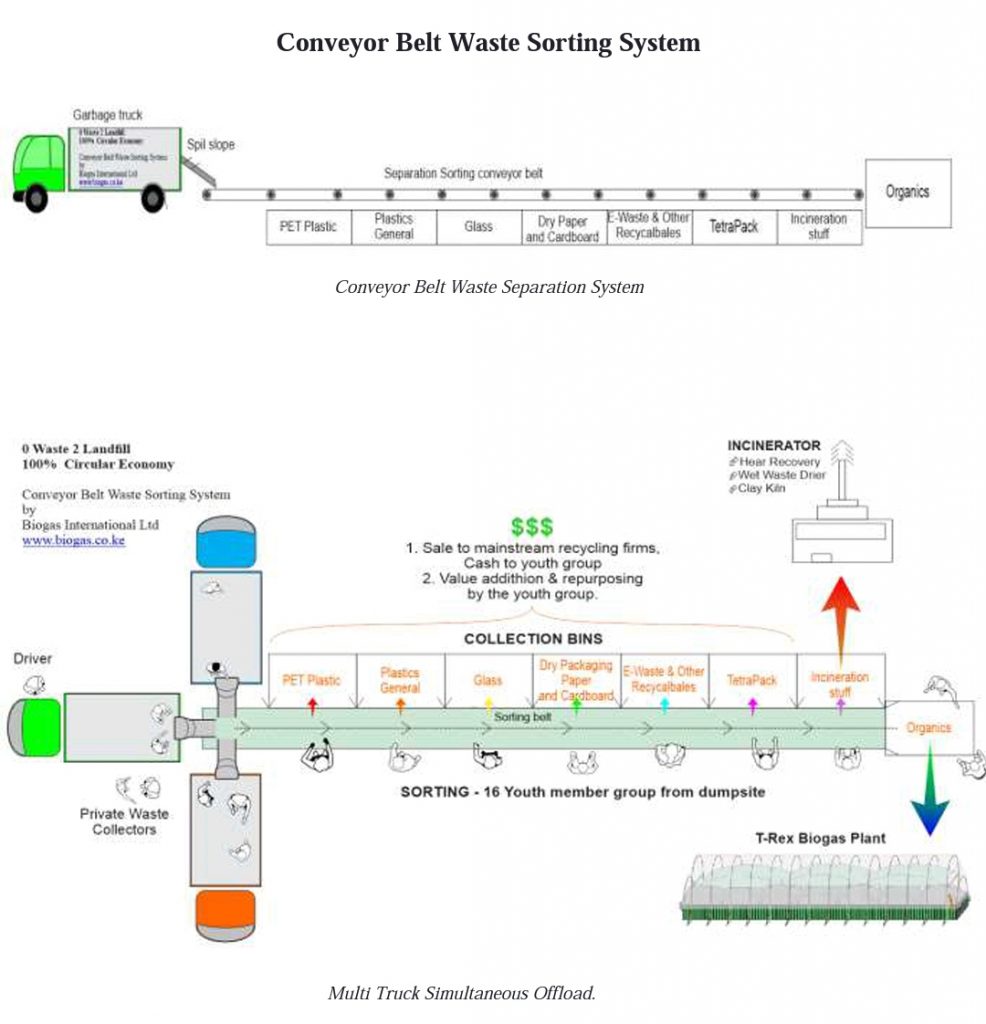

WASTE SEGREGATION

A key to the success of ease of operation is the separation of the waste into 3 main categories.

1. Organic material

– Market waste

– Kitchen waste

– Commercial food waste

2. Recyclable materials

– Plastic’s

– Glass

– Paper

– Tetra Pack

– Ceramic’s

– Electronics & Batteries

3. Non-recyclable materials

– Diapers

– Wet carton and packing

– Cloth

– Shoes

– Single use plastics

In Markets

Waste Collection Vehicles

Private waste collectors from town businesses and residential estates

WORKFORCE & JOB CREATION

– We will engage youths the waste pickers form the dumpsite to manage the sorting belts.

– Alike the model in Kitengela, in return for their time, the waste pickers / separators will own all the reusable items and materials they remove from the waste belt. BIL will manage the organic material and the remaining useable waste.

– We will aid them in finding markets for these sorted materials.

– We will also train interested pickers on the different value addition skill, so they can generate higher incomes.

URBAN ENERGY BIOGAS-ON-TAP

At Biogas International Ltd – BIL, we have developed a 1 Stop Urban Waste Management Solution designed to manage waste at source. All waste is sorted and recycled appropriately at source, eliminating greenhouse gas emissions and substantially reducing carbon emissions.

This circular economy design eliminates the need for transporting waste to landfills and in doing so will save the tax payers millions in associated costs.

Replacing charcoal with biogas in homes, restaurants, communal kitchens etc will reduce deforestation.

The clean burning biogas will also have immeasurable health benefits, especially to women and children in their cooking environment.

ORGANIC LIQUID BIO-FERTILISER

What goes in must come out, and does so in the form of a rich organic compost tea. This can be applied as a fertiliser to topsoil, fed through sprinklers or drip-line irrigation systems, or added to compost for building healthy topsoil.

When sprayed on crops as a foliar feed, the bio-tea also doubles as an extremely effective pest repellent on crops.

Considering that the inputs material to the digesters is fresh organic material and not dung, the bio-tea also double as a livestock feed supplement.

ENRICHED ORGANIC COMPOST

JOB CREATION

JOB CREATION

The model also creates employment, and will attempt to develop the skills of youth who demonstrate a keen liking to the biogas big picture.

BENEFITS

– The organic waste will be fed to the Biogas Plant

– All the different types of waste will sold to the appropriate recyclers.

– Heat-recovery incineration of useless undesirable waste such as diapers, cloth, shoes etc

– BioGas sold used to offset the use of charcoal

– Bio-Fertilisers sold to farmers

– Youth and Women groups will be trained in waste collection and separation.

SUSTAINABILITY

Social Enterprise Model

The business model set up as that of a social enterprise with low profit to cover running costs. Income generated will go into running the plant and profits put towards replicating the model in other areas.

Income Streams

1. Biogas

Gas generated is piped directly to points of use, for example communal kitchens, and via a mini-grid network to domestic homes.

The gas is sold. The payment models will vary from user to user. The different methods include

i. Metered gas – Prepaid or/and PAYG

ii. Communal kitchens -PAYG

iii. Daily timed cooking periods – Prepaid

iv. Portable balloons – PAYG

2. Organic Fertiliser Compost Tea Fertiliser / Livestock Supplement

A second income stream will be through the sale of fertiliser. The brokers that bring fresh vegetables and fruits to the market place will be trained to broker the fertiliser back to their farmer clients.

The model will also encourage the charcoal hawkers to broker fertiliser and gas to their regular clients.

3. In-house value addition to recyclables

a. E waste gold extraction

b. Plastics to oil and / or moulded products

c. Aluminium and cast to moulded products

d. Others

4. Sale of other recyclables

a. Plastic

b. Metal

c. Glass

d. Paper

5. Non Recyclable’s

a. Level 1 – Toxic waste, chemicals, etc

1. To appropriate disposal facilities

2. Heat recovery incineration at high temperature.

b. Level 2 – dirty assorted waste

Mixed waste – glass, plastics, ceramics, etc

1. Shredded / powdered and sealed away into interlocking housing bricks – Addressing the low income housing challenge.

https://www.youtube.com/watch?v=P2jyLjL1-Wc

VERSATILITY

VERSATILITY

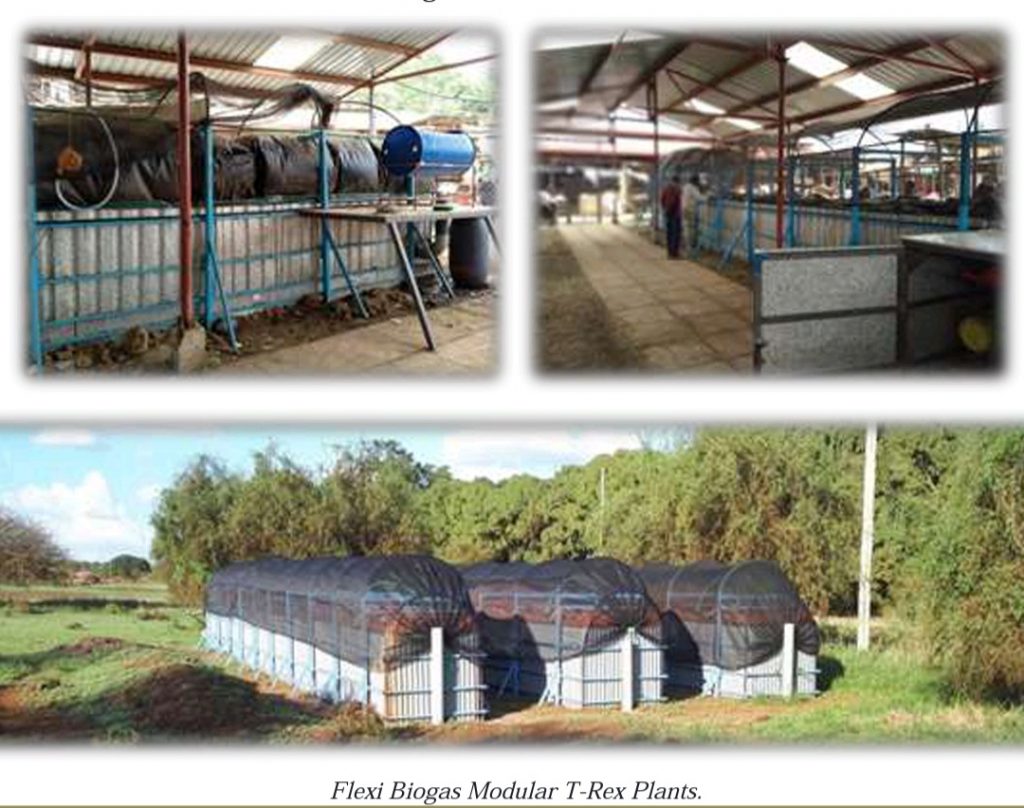

Our T-Rex digesters are prefabricated and modular allowing for relocation, upgrading or removal. Installation is only a few days for smaller plants, and a couple of week for sizeable plants.

Gas-up is within a couple of 14 days.

T-Rex Large Capacity Biogas Technology

T-Rex T15 at Dagoretti Slaughterhouse – Gas used in cafe

BIO-SAN-GAS TECHNOLOGY

Hygienic human waste management solution.

We have also developed hygienic PAYG Public Toilets and Showers that also produces biogas. These systems can be installed in schools or as Pay As You Go – PAYG public toilets.

The biogas can be used for cooking, heating bathing water etc.

Bio-Fertiliser and Grey Water management

– The bio-fertiliser from these systems is channelled through shallow French Drains along boundaries, hedgerows etc

– Grey water is treated with EM and recycled for irrigation and possibly toilet flush water.

– To benefit from the 24/7 nutrient rich irrigation system, fruit trees are planted along the drains.

COPYCAT FARMING

Climate Smart Organic Regenerative Vertical Farming – Beyond Permaculture.

Cone gardens under shade-net with drip irrigation Yields 3 – 4 times higher than conventional ground farming.

SUSTAINABILITY & BUSINESS MODEL

To guarantee sustainability, the model has to have a business angle where the sale of services and products generate income to sustain the operational expenses, as well as reasonable profits for expansion.

Income streams include

1. Sale on biogas

2. Sale of liquid fertiliser & Compost

3. Sale of farm produce

4. Sale of fruit tree seedling

5. Sale of veggy and herb seedlings

6. Sale of value added products

– dried fruits & fruit leathers

– yogurt & smoothies

– cooking services

7. Fish drying services

8. Farm training programs

9. Hot showers

10. Laundry services

11. Visit to site

Every location has unique needs, and we can provide the services. The numerous opportunities will create entrepreneurship and employment,

… and the environment wins by default

ZERO WASTE TO

LANDFILL!!

“RENDERING LANDFILLS OBSOLETE”

Biogas International Ltd

www.biogas.co.ke

biogasinternational@yahoo.com

Excellent knowledge. Many thanks.