T-Rex Technology

LARGE CAPACITY

BIOGAS PLANTS

“T-REX TECHNOLOGY SYSTEMS”

The T-Rex digesters are highly efficient large capacity systems with high gas production designed for Farms, Children’s homes, Universities & institutions, Schools, Hotels and anywhere with a high-energy demand.

The systems are also designed as waste management devices for market places, municipal waste management etc.

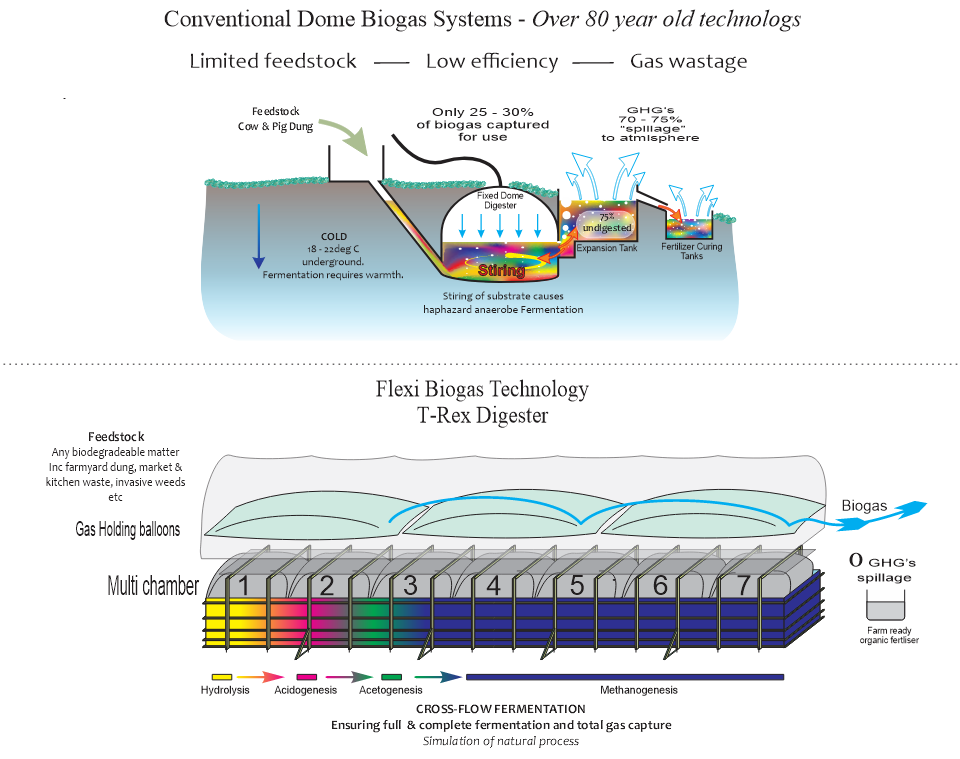

T-Rex systems are modular making the plant easily scalable to meet the client requirements. The system is of longitudinal “True Cross Flow” methodology, or you could say a continuous batch-flow.

This meaning anything fed in the inlet end will be forced to flow the full length of the system (minimum retention period of 25-40 days) whereby getting fully digested, and having given off all the biogas potential by the time it overflows the exit as a rich organic fertilizer and pest repellent.

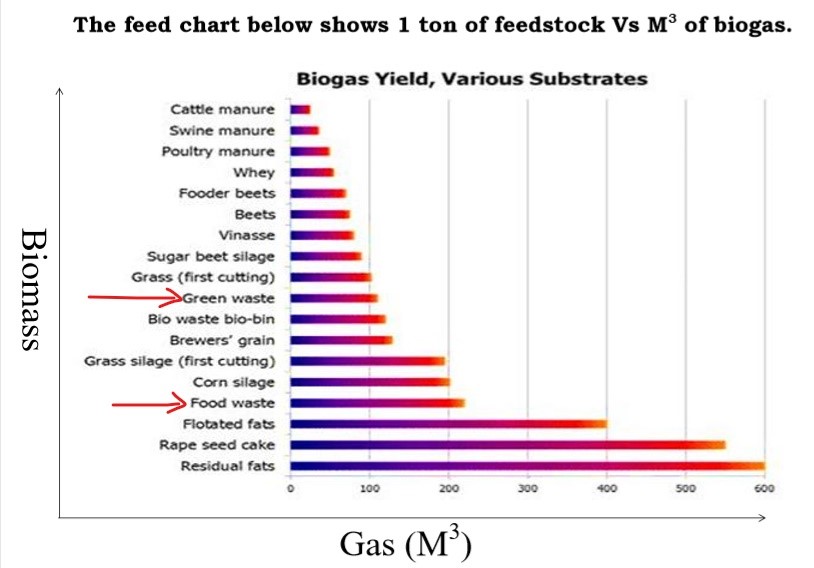

The T-Rex biogas plants runs on any bio-degradable material as feedstock and therefore does not limit the user to use of only cow dung.

All our plants are designed with the operator in mind – simple to understand and operate. Feed one end, a turn or two of the agitation wheel, and the system does the rest. Gas is piped directly to the point of use, and “Ready To Use” bio-fertiliser automatically overflows from the opposite end into a collection tank.

Flexi Technology was born out of over 20 years of research and development and in consideration of all aspects and inefficiencies associated with conventional constructed biogas technologies.

KEY ATTRIBUTES OF THE FLEXI-TECHNOLOGY T-REX BIOGAS PLANT

1. Prefabricated

Flexi Biogas systems are prefabricated and installation happens in a few days.

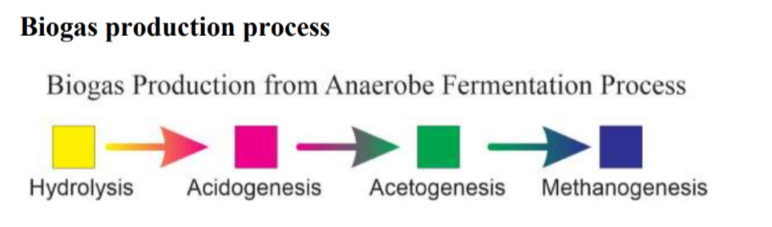

2. Cross-flow fermentation

Flexi-Tech employs a multi-chamber ”True Cross-flow” fermentation process, which means that what goes in one end is fully processed before exiting the system from the opposite end.

The multi-chamber design provides a constant retention time for all the substrates, ensuring that no new feed can short-chase to the exiting end. This also means 100% of the biogas being captured making Flexi-Tech the GREENEST biogas plant design yet.

3. Runs on all bio-degradable material

The primary benefit of Flexi-Tech over all conventional and other prefabricated systems is unlike other technologies that are dependent specifically on animal dung – cow and pig dung, Flexi-Tech is designed to run of virtually all and any biodegradable materials. This includes livestock dungs, poultry droppings, kitchen and market, agro-processing waste, invasive weeds such as Opuntia Cactus, Water Hyacinth, Prosopis Juliflora – Mathenge, Dodder Cascuta, just to mention a few.

Points to Ponder

- Wherever there are people, there is water.

- Where there is water, something is growing.

- With Flexi-Tech, anything growing will produce biogas and rich organic fertiliser.

4. Applicability

In Kenya where only 1.7 million dairy farmers qualify for conventional biogas technology, the entire population of Kenya and beyond qualifies for Flexi-Tech systems.

5. Scalable

As energy demand increases, the system can easily be scaled. Not possible/farm more complicated with Dome systems.

6. Plug & Play Turn-key Technology

Flexi Biogas systems are 100% prefabricated with a minimum level of technical skill to install and operate. This also means the systems can easily be relocated or up-scaled should the need arise.

7. Quick Start-up

After installation, the systems will have usable volumes of gas within 7-14 days and are normally in full production within 20-25 days.

8. Rich organic Fertiliser

As we are aware, fertile soil is the key most important component in the production of quality foods. In developing countries, fertilizer is also the most expensive input in crop production.

Not with Flexi-Tech. To add to the list of advantages of the system, the overflowing bio-fertilizer from the system is a highly nutritious fertilizer and ready for absorption by plants without ‘burning the plants’. Diluted to 1:5 or 1:10, it is applied as a top dressing or sprayed as a folia feed: Sprayed on, it has also proven extremely effective to be an insect repellent.

Read more about the use and benefits of Bio-fertiliser here;

https://biogas.co.ke/bio-slurry/

T-REX SIZING, FEED RATE AND COST

| MODEL | CAPACITY M3 | LENGTH | WIDTH | HEIGHT | MODULES |

DAY INSTITUTION/ ONE MEAL PER DAY |

BOARDING INSTITUTION/ THREE MEALS PER DAY |

DAILY FEED RATE IN KILOS (GREEN WASTE + WATER) |

COST (KENYAN SHILLINGS) |

| T30 | 30M3 | 9 | 2.5 | 1.5 | Single Module | 150 | 75 | 240 | 765,000 |

| T50 | 50M3 | 15 | 2.5 | 2.5 | Single Module | 250 | 125 | 400 | 1,200,000 |

| M100 | 100M3 | 21 | 3.6 | 2 | Single Module | 500 | 250 | 800 | 1,600,000 |

| M200 | 200M3 | 21 | 7.2 | 2 | Twin Modules of 100m3 each | 1000 | 500 | 1600 | 3,200,000 |

- please note:

In a boarding institution (or a facility where people are served 3 meals per day per person), 1m3 of biogas will cook for approximately 5 people. - In a day institution (or a facility where people are served 1 meal per day per person), 1m3 of biogas will cook approximately 10 people.

- The systems are modular and scalable to meet the energy demand.

INSTALLATION AND PLUMBING

- There is no restriction to the distances between the digester and the point of use, although for management purposes we recommend the shortest possible distances.

- As the T-Rex digesters do not produce any gas pressure, the gas is pumped to the various point of use.

- The “Auto Pressure Switch” provides a constant pressure in the plumbing, and as soon as there is a pressure drop in the system meaning somewhere a user has turned on the gas, the pump is powered up.

- The pump or pumps can be run on a 50W Solar PV system or on mains power.